Category management:

what it is and why it's needed

Category management is a comprehensive approach to managing a product assortment, where each product category is treated as an independent business unit. In modern retail, particularly in the context of commerce, efficient assortment management has become key to a company’s success. The essence of this management style lies in effectively dividing all products into groups and organizing their sales in such a way that both satisfies customer needs and increases profitability. This method not only enhances customer interaction but also optimizes supply processes, reducing costs and boosting product turnover.

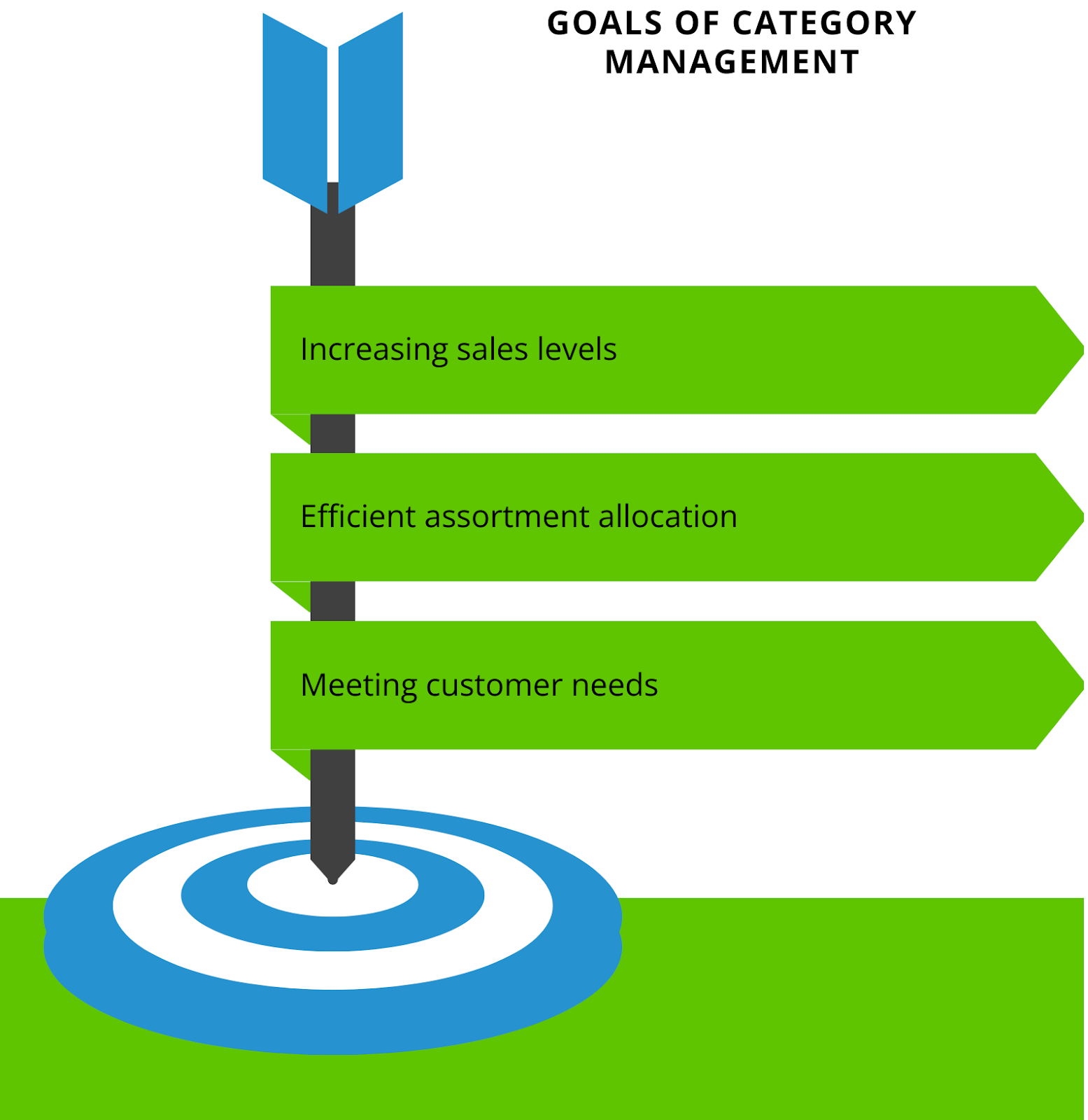

A category is not just a set of products; it is an independent unit with its own objectives, budget, and a sales growth plan. The primary goal is to optimise the assortment, increase product turnover, and meet consumer needs.

This approach was first implemented in the 1990s by “Procter & Gamble” and quickly gained traction among retailers worldwide. It is based on the analysis of sales data, customer preferences, and collaboration with suppliers and manufacturers.

Category management is in high demand in retail, as it enables businesses to streamline their product range, improve turnover, and enhance customer loyalty by offering the right products at the right time. In a highly competitive market, this becomes a crucial factor for any store's success.

This approach was first implemented in the 1990s by “Procter & Gamble” and quickly gained traction among retailers worldwide. It is based on the analysis of sales data, customer preferences, and collaboration with suppliers and manufacturers.

Category management is in high demand in retail, as it enables businesses to streamline their product range, improve turnover, and enhance customer loyalty by offering the right products at the right time. In a highly competitive market, this becomes a crucial factor for any store's success.

What is category management

Category management is a strategy for managing product categories, where products are grouped based on their function and customer demand

Curiosity about life in all its aspects, I think, is still the secret of great creative people.

The goal of category management is to ensure maximum efficiency in assortment management, increase revenue, and meet customer needs. The strategies behind this approach are based on a thorough analysis of the market, product variety, and consumer behaviour.

Strategies, goals, and principles of category management

- Demand analysis: This is the starting point for building an effective strategy. At this stage, it is crucial not only to understand which products are popular but also to predict shifts in customer preferences. Demand analysis involves studying current market trends, customer behaviour, and sales dynamics. This helps identify products that need more attention and determine categories where sales potential can be increased.

- Managing product categories: This process involves grouping store products according to various criteria, such as functionality, target audience, or demand level. Each product category is treated as a separate business unit with its own goals and objectives. This approach allows each category to be managed independently, simplifying stock control, supplier relations, and sales planning. It is essential for each category to have clearly defined parameters, including a budget and a plan for profit growth.

- Assortment optimisation: A key principle aimed at structuring each product category to maximise sales. This is achieved through careful supply planning, taking customer preferences into account, and continuously monitoring stock availability. Optimisation involves removing non-performing products and adding new items that might attract customer interest.

Key principles of category management

To successfully implement category management, various tools are used to help companies manage their product assortment, optimise procurement processes, and improve customer satisfaction. One of the key tools is data analytics, which enables the evaluation of sales dynamics and identification of key product types.

Key tools of category management

This is a crucial management tool. It helps identify the most popular products and those that require optimisation. By evaluating data, businesses can better plan their supplies and adjust their store's assortment.

Sales analytics

With this tool, entrepreneurs can plan their purchases in advance, based on the analysis of past sales and market trends. This helps prevent stock shortages or overstocking.

Demand forecasting

Properly distributing products by category and regulating their quantity in the warehouse minimises unsellable stock and reduces storage costs.

Inventory management

The category manager is responsible for liaising with suppliers and overseeing product deliveries. Effective supply planning allows for optimised stock turnover and reduced company expenses.

Procurement planning

Category management involves a multi-stage decision-making process aimed at improving assortment efficiency and increasing revenue. Each stage of this process is based on sales data and customer preferences.

- Data collection – the first stage in decision. Making involves analysing sales data, demand for specific product types, and interactions with suppliers.

- Data analysis – based on the collected information, the manager evaluates the effectiveness of the current product range and identifies items that need optimisation.

- Decision-making – after evaluating the data, decisions are made regarding how to allocate products across categories, which items should be removed from the assortment, and which should be added.

- Adjustment – depending on changes in demand and analysis results, the manager adjusts the assortment to better meet customer needs.

The decision-making process in category management

Implementing category management is a multi-stage process that requires careful preparation and a systematic approach. Each stage aims to enhance assortment control, improve supplier relationships, and increase customer satisfaction. Below are the key steps necessary for successful implementation:

Stages of implementing category management

The first stage involves an in-depth analysis of the current product range. The manager reviews data on sales performance, profitability, and customer behaviour. Key product types and items with the greatest potential for growth or needing adjustment are identified. It's important to consider seasonal demand shifts and external factors like economic changes and consumer trends. This analysis helps determine which items should remain, be removed, or added to the assortment.

- Assortment analysis

After the assortment analysis, the next step is to create product categories. Items are grouped based on factors such as function, demand, or target audience. Each category is treated as an independent business unit with its own goals, budget, and concept. This helps organise the assortment in a way that makes it easier for customers to navigate. Category managers must also consider factors such as product placement in the store, visual appeal, and the strategic importance of each category.

2. Defining product categories

At this stage, an individual strategy is developed for each category. This includes planning purchases, controlling inventory, forecasting demand, and developing marketing activities to stimulate sales. The manager sets a budget for each category, plans promotions and discounts to maintain customer interest, and focuses on working closely with suppliers to ensure timely deliveries and minimise costs.

3. Developing category management strategies

It's essential to define KPIs for each product category. These indicators help monitor results and adjust strategies as needed. For example, one category's KPI might focus on revenue growth, while another might focus on improving stock turnover. Defining specific goals and KPIs for each category ensures better control of the process and achievement of the desired outcomes.

4. Setting key performance indicators (KPIs)

Building strong supplier relationships is a crucial step. This includes selecting reliable partners for long-term cooperation. The category manager negotiates the best supply terms, including pricing, delivery times, and order volumes. Effective supplier management helps reduce logistics costs, ensure consistent stock availability, and improve profitability.

5. Supplier relations

As part of supplier collaboration, attention must also be paid to logistics. Establishing efficient delivery processes to stores is key to minimising costs and avoiding stock shortages. Optimising logistics reduces delivery times, improves inventory management, and cuts company expenses.

6. Logistics optimisation

After implementation, continuous monitoring of results and strategy adjustment based on market changes is essential. This includes evaluating sales performance, stock turnover dynamics, customer preference shifts, and competitor actions. Regular monitoring helps identify problem areas and take corrective action. For instance, if a category loses popularity, the promotion strategy may need revisiting, or the products in that category may require replacement.

7. Monitoring and adjusting the strategy

Category management is a vital tool for assortment management, helping companies work effectively with product categories, enhance customer interactions, and increase profits. Although its implementation requires careful planning and data analysis, it offers significant long-term benefits.

- Category management enables companies to manage their product range more efficiently.

- Assortment optimisation boosts sales and enhances customer loyalty.

- Data analytics improves purchase planning and demand forecasting.

- Supplier collaboration plays a key role in successful execution.

- Continuous monitoring and adjustment of the assortment strategy help businesses adapt to market changes and meet customer needs.

Conclusion

Tilda Publishing