How to get rid of unsellable stock: five proven solutions

The issue of unsellable stock is familiar to anyone working with inventory: whether it's a shop owner, purchasing manager, or category manager. Mistakes in demand forecasting, over-purchasing, and changes in market conditions all contribute to certain products becoming "dead weight". If not addressed in time, unsellable stock can pose a serious threat to a company’s financial health.

However, there is good news: unsellable stock can and should be dealt with. What's more, it's not as difficult as it may seem at first. In this article, we will explore 5 proven solutions that will help you get rid of unsellable stock, free up warehouse space, and return money to circulation. These methods have already proven effective in various companies, and you can apply them to your business today.

Unsellable stock is a headache for any business. Products that gather dust in the warehouse for months not only fail to generate profit but also drain resources. They "freeze" money, hinder the purchase of new stock, and ultimately lower overall profitability. But the most troublesome aspect is that many companies don’t even know how to properly identify unsellable stock and what to do with it.

What is unsellable stock and why does it occur?

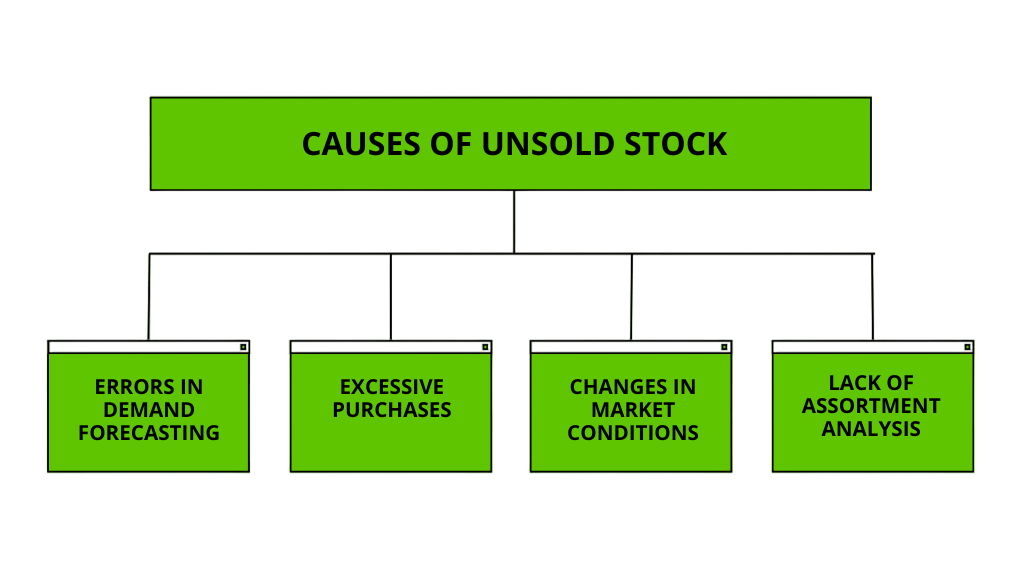

The issue of unsellable stock is familiar to many companies, and the reasons for its occurrence can vary. Let’s examine the main ones:

Unsellable stock refers to products that do not attract demand from customers and end up sitting in warehouses. These products can either be completely unsought (with no sales for a long period) or slow-moving (with extremely low turnover). In either case, such items become a burden for the business as they do not generate profit but only occupy space, tying up financial resources.

A company may purchase a batch of goods expecting high demand, but the forecasts turn out to be incorrect. For example, you may have ordered a large quantity of summer dresses, but the season turns out to be cold, and customer activity drops sharply. As a result, the product remains in the warehouse, turning into unsellable stock.

Errors in demand forecasting

Without a clear system for controlling purchase volumes, retail businesses often acquire more stock than needed — "just in case." For example, in anticipation of a seasonal surge in popularity, buyers increase their orders, but the actual demand turns out to be much lower than expected.

Excessive purchases

A product that was popular in the previous season may lose demand due to new trends or changing customer needs. For example, an outdated smartphone model can become unsellable after the release of a new version.

Changes in market conditions

If a store does not track which products sell well and which do not, unsellable stock will accumulate unnoticed. For example, a product that sold slowly but steadily can become unsellable if it is not removed from the assortment in time.

Unsellable stock can exist in any market niche. For example:

- Retail: last season’s clothing that remains in the warehouse.

- DIY (home and repair products): materials that were over-purchased but have lost relevance.

- Wholesale: products that were bought for a specific customer, but the order never arrived.

Lack of assortment analysis

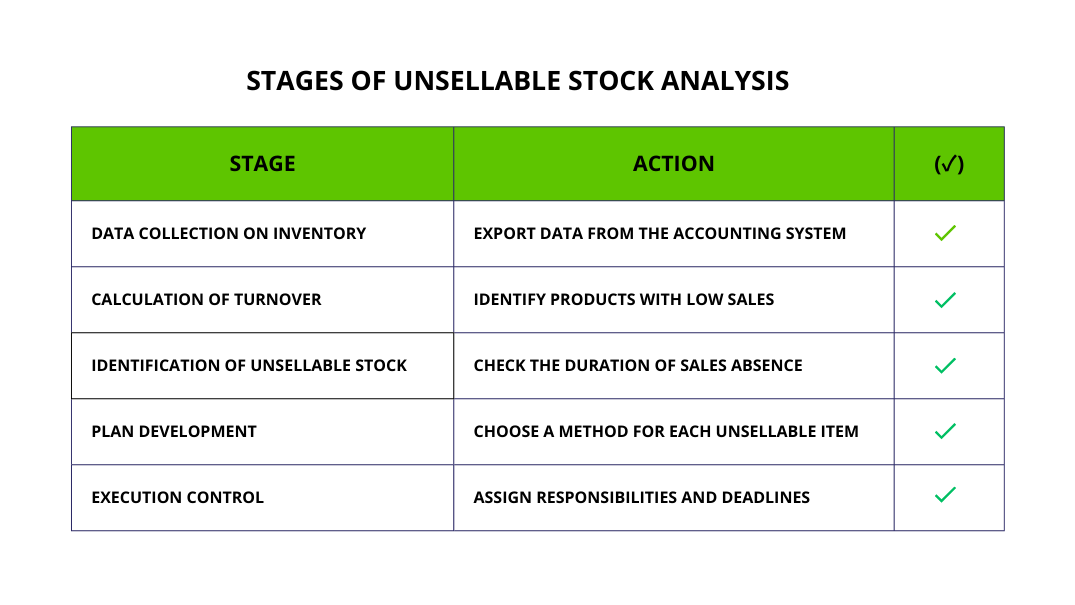

To effectively tackle unsellable stock, it is essential to identify it correctly. This requires clear criteria and a systematic approach to data analysis. Let’s explore how to do this.

How to identify unsellable stock?

The main parameters for identifying unsellable stock are:

Criteria for identifying unsellable stock

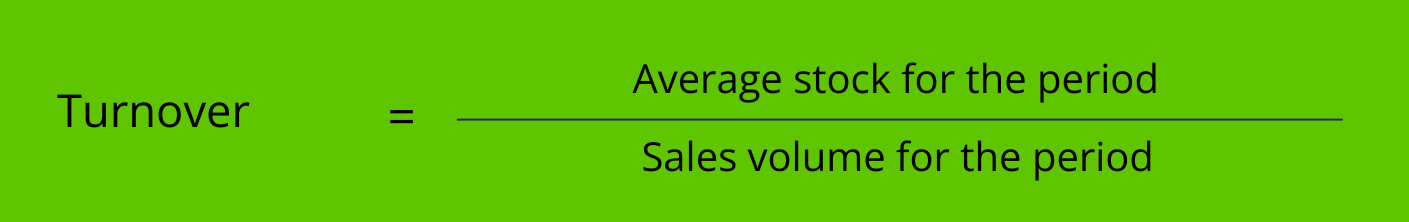

Turnover below average

Turnover shows how quickly a product sells. If it is significantly lower than the average for your category, this signals a problem.

For example: in the DIY niche, the average turnover is 3 months, but your product’s turnover is 12 months.

Turnover shows how quickly a product sells. If it is significantly lower than the average for your category, this signals a problem.

For example: in the DIY niche, the average turnover is 3 months, but your product’s turnover is 12 months.

Lack of sales

A product that hasn’t sold over a certain period (e.g., 6 months) can also be classified as unsellable stock.

A product that hasn’t sold over a certain period (e.g., 6 months) can also be classified as unsellable stock.

Low sales relative to inventory

If a product sits in the warehouse in large quantities but sells only in small numbers, this is a clear sign of unsellable stock.

For example: 1000 units in stock, with only 10 sales per month.

If a product sits in the warehouse in large quantities but sells only in small numbers, this is a clear sign of unsellable stock.

For example: 1000 units in stock, with only 10 sales per month.

Let’s consider a simple example:

Inventory in stock: 1000 units

Sales per month: 10 units

Turnover: 1000 / 10 = 100 months (more than 8 years)

Inventory in stock: 1000 units

Sales per month: 10 units

Turnover: 1000 / 10 = 100 months (more than 8 years)

Example of calculation

This calculation shows that the product will take over 8 years to sell, making it a clear case of unsellable stock.

For effective management of unsellable stock, it is crucial to implement systematic tracking. Here are the key steps:

Importance of systematic tracking

- Add a "unsellable" label to the product card. For example, if you use 1C system, create a special field for marking unsellable stock. This will simplify their identification.

- Organize inventory by descending value. Start dealing with the largest unsellable stock items. For example, if one product "freezes" 500,000 rubles and another one 50,000, it’s clear that you should start with the first.

- Regularly analyze the data. Set a schedule (e.g., once a month) for analyzing inventory and identifying new unsellable stock.

Unsellable stock is a problem that won’t resolve itself. If no active measures are taken, it will continue to take up space in the warehouse and block cash flow. However, there are several effective methods that can help you deal with this situation. Let’s take a closer look at them.

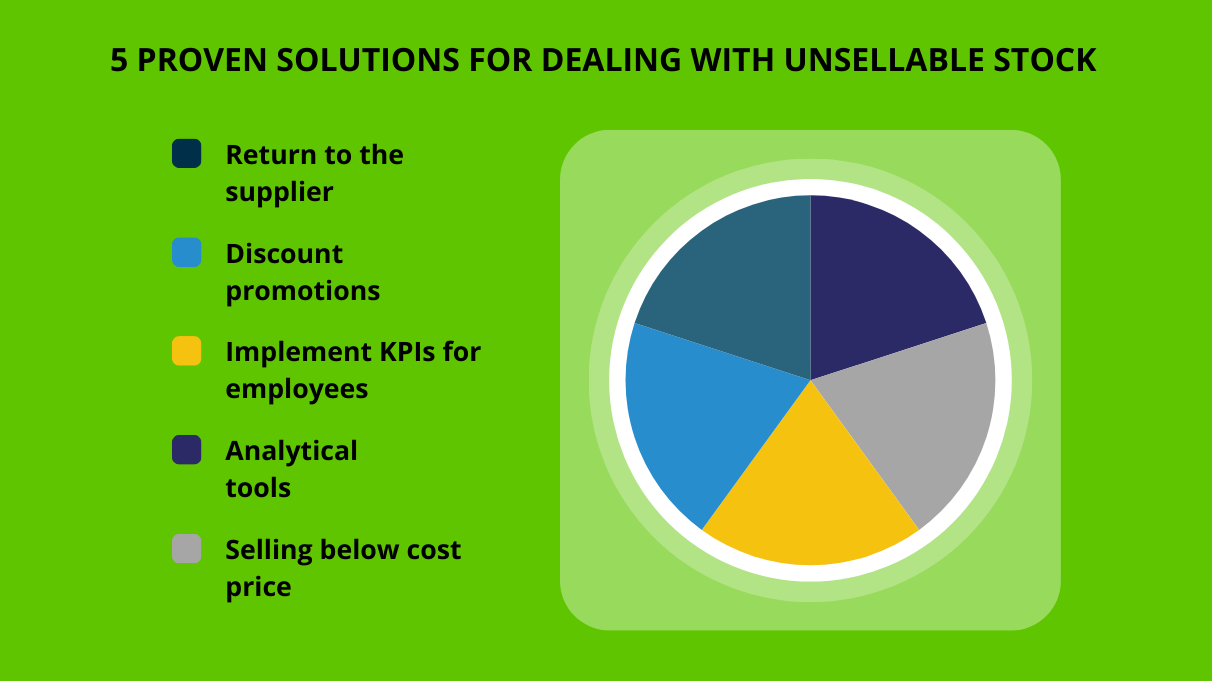

5 proven solutions for dealing with unsellable stock

One of the easiest ways to get rid of unsellable stock is to return it to the supplier. However, it is important to outline the return conditions in the contract in advance. For example, you can agree on partial returns or exchanging products for more in-demand items.

Solution 1. Return to the supplier

Which products can be returned and which cannot?

- Can return: Products that are unopened or undamaged, especially if this is outlined in the contract.

- Cannot return: Products with expired shelf life or those damaged during storage.

How to negotiate with suppliers?

- Clarify the possibility of returns or exchanges before signing the contract.

- Discuss return conditions if the product hasn’t been sold within a certain period.

- ffer alternatives, such as exchanging goods for others or returning part of the amount.

A sale of unsellable stock with discounts is an effective way to recover at least part of the invested funds. However, it is important to organize the promotion correctly so that it doesn’t harm the brand image.

Solution 2. Deep discounts for customers

How to avoid damaging the brand image?

- Avoid using the word "clearance" — replace it with "special offer" or "promotion."

- Emphasize that the discounts are related to the end of the season or an assortment update, not the poor quality of the product.

How to organize a sale?

- Create a separate category, such as "Promotion" or "Special Offer" on your website or in-store.

- Set discounts from 30% to 70% to stimulate demand.

- Use marketing tools: email campaigns, banners, and social media ads.

Employee motivation is one of the key factors in successfully dealing with unsellable stock. Implementing KPIs (Key Performance Indicators) will help make the process more systematic.

Solution 3. Implementing KPIs for managers

Example of KPIs

- Reduce the proportion of unsellable stock from 15% to 5% within 6 months.

- Sell 80% of unsellable stock within 3 months.

How to monitor KPI performance?

- Use reports from CRM or accounting systems.

- Hold monthly meetings to discuss progress.

How to motivate managers?

- Set KPIs related to the proportion of unsellable stock in the total inventory and the timeframes for selling them.

- Introduce bonuses for meeting or exceeding targets for reducing unsellable stock.

- Regularly analyze and discuss results.

Automating the tracking of unsellable stock significantly simplifies the process of identifying and managing it. Modern analytical tools allow you to monitor inventory, turnover, and other key metrics.

Solution 4. Using analytical tools

How to implement the tools?

- Start by analyzing current processes and identifying bottlenecks.

- Choose tools that fit your needs and budget.

- Train employees to use the new systems.

Example of successful use of analytics

A company in the DIY segment used Greenshelf to analyze inventory. As a result, they managed to reduce the proportion of unsellable stock from 20% to 8% over the course of a year.

A company in the DIY segment used Greenshelf to analyze inventory. As a result, they managed to reduce the proportion of unsellable stock from 20% to 8% over the course of a year.

Which tools to use?

- Greenshelf: Assortment planning and inventory management.

- Excel: For small companies, spreadsheets can be used to calculate turnover.

In some cases, it makes sense to sell unsellable stock even below cost price. This will at least allow you to recover part of the invested funds and free up space in the warehouse.

Solution 5. Selling below cost price

How to organize a sale?

- Set a price that will cover part of the costs.

- Hold an internal sale for employees — they can be the first target audience.

- Use distribution channels such as marketplaces or wholesalers.

When to use this method?

- If the product doesn't sell even with discounts.

- If storage costs exceed the potential profit from selling the stock.

Not all products sitting in the warehouse are unsellable stock. Some of them may be strategic reserves or seasonal items. It is important to distinguish such products so that they are not written off as unsellable stock, thus avoiding the loss of potential profit.

Exclusions from unsellable stock

Some companies deliberately keep products in stock that may be needed in the future. This is especially relevant for industries where raw material or component prices frequently change, or for products whose supply may be disrupted.

1. Strategic reserves

How to identify strategic reserves

- Analyze historical data on demand and prices.

- Monitor the market and forecast potential changes.

- Set storage limits for such products to ensure they don’t turn into unsellable stock.

Examples

- Construction companies stock up on materials before the season to avoid price increases.

- Electronics manufacturers keep spare parts for device repairs that may be needed during the warranty period.

Products that are in demand only during a specific time of year should not be considered unsellable stock, even if they sit in the warehouse for most of the year.

2. Seasonal products

How to manage seasonal products

- Plan purchases with seasonality in mind.

- Organize sales at the end of the season to minimize inventory.

- Store such products until the start of the next season, if their storage is economically justified.

Examples

- Summer clothing, which is only in demand during the warm season.

- Christmas decorations, which see a sharp increase in demand in december.

Some products simply sell slowly, but that doesn’t make them unsellable stock. For example, this could include expensive electronics or exclusive products.

3. Products with a long sales cycle

How to manage such products

- Set reasonable turnover times for these products.

- Do not classify them as unsellable stock if their sales are stable.

- Ensure that the storage costs for such products are justified.

Examples

- Premium household appliances, where sales might be only a few units per month.

- Unique handmade items, which find their buyers, but not immediately.

Some retailers keep products in stock that may be needed for fulfilling special orders, such as specific equipment or materials. This is common for construction companies working on specific projects, as well as manufacturers handling custom orders. To manage such products effectively, it is important to track the order fulfillment timelines to ensure they don’t stay in the warehouse too long, and to make sure that their storage is economically justified. An optimal solution could be purchasing such products based on specific orders, which would help minimize warehouse stock.

4. Products for special orders

Unsellable stock is not just a problem; it is a call to action. It signals potential errors in forecasting, purchasing, or inventory management. However, if you approach the issue systematically, unsellable stock can not only be minimized but also turned into a tool for increasing business efficiency.

In this article, we discussed what unsellable stock is, why it occurs, and how to deal with it. Here are the key points to remember:

In this article, we discussed what unsellable stock is, why it occurs, and how to deal with it. Here are the key points to remember:

Conclusion

- Unsellable stock consists of products that either don’t sell or sell too slowly. Their presence is not just a loss but also a missed opportunity for business development.

- The reasons for their appearance can vary: from forecasting errors to changes in market conditions. The main thing is to identify and address these causes in time.

- Tackling unsellable stock requires a comprehensive approach. Returning stock to the supplier, running sales, motivating employees, and using analytical tools all help to effectively solve the problem.

- Not all products in the warehouse are unsellable. Strategic reserves, seasonal items, and products with a long sales cycle often require a different approach.

It is important to remember: unsellable stock is not a sentence, but an opportunity for improvement. Regular inventory analysis, the implementation of modern tools, and a systematic approach to assortment management will help you not only get rid of unsellable stock but also prevent it from arising in the future.

Now, you have all the necessary knowledge and tools to start taking action. Conduct an audit of your inventory, select the appropriate methods, and take the first step toward more efficient stock management. Your business deserves to operate without unnecessary losses!

Tilda Publishing